Werfen Sie einen Blick auf die Anwendungen von Schaumstoffen für Flightcases mit Diskussionen über ihre Unterschiede

Zweitbestes ist keine Priorität für Sun Case Versorgung, sowie ein Katalog mit Koffern aus Aluminium. Zu ihrem Angebot gehören auch Schaumstoffe. Ihre Kunden finden verschiedene Arten dieser Schaumstoffe aus dem Katalog dieser Herstellermarke, darunter Koffer für Industriewerkzeuge, Sportkarten, Schallplatten, Tierpflegekoffer und Waffenkoffer.

Zwei der gängigsten Materialien für diese Artikel sind vernetzter Polyethylenschaum, auch bekannt als XPE-Schäume, und EPEs (expandiertes Polyethylen). Erfahren Sie in diesem Vergleichsleitfaden mehr über die Unterschiede dieser Materialien – von den scheinbar hybriden bis hin zu den effizientesten für ihre Anwendung. Dabei werden die folgenden Punkte behandelt:

– Welche Schäume gibt es für diese Anforderungen?

– Schaumstoffe für Flightcases + ihre Anwendungen

– Die Unterschiede zwischen solchen Schäumen

Weiterlesen: Lernen Sie diese Schäume für diese Vorräte kennen

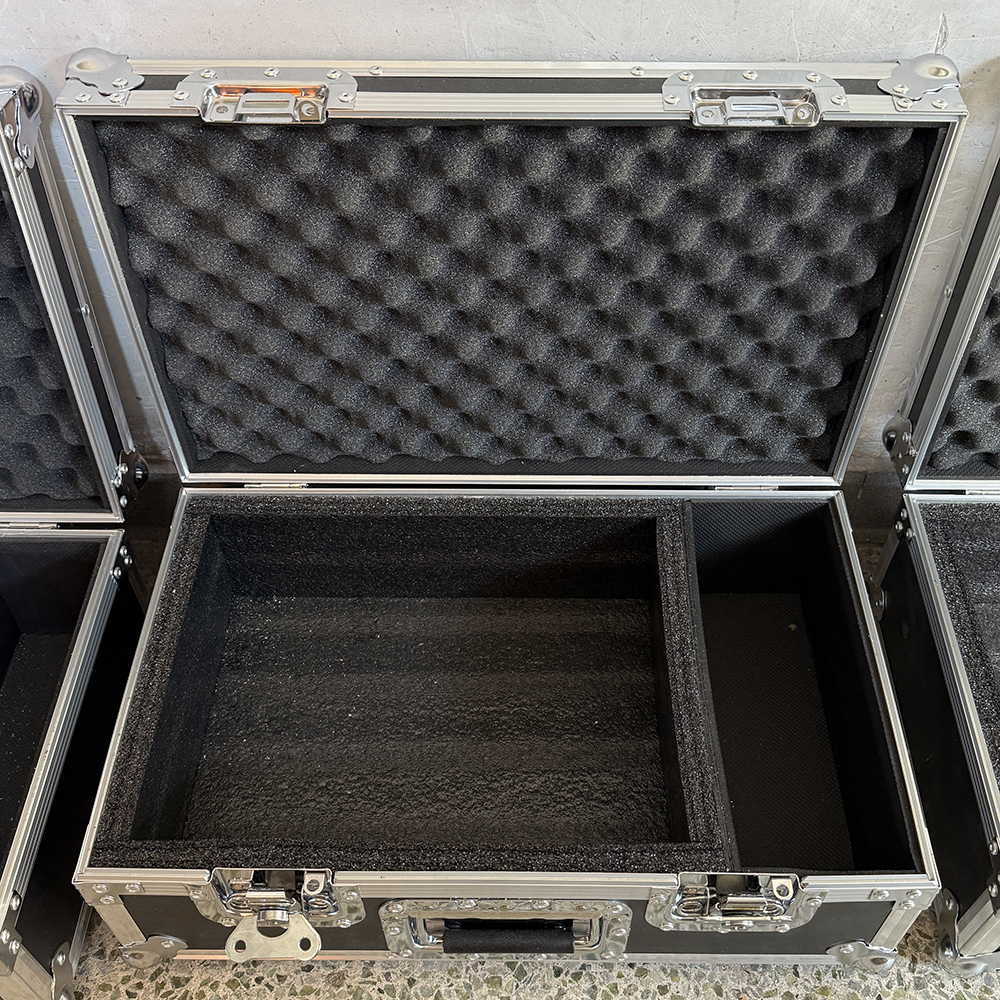

Schaumstoffe für Zubehör, von denen für Gitarren-Flightcase-Sets bis hin zu verschiedenen Flightcase-Teilen verwendet werden, sind Materialien, die ihren Benutzern die Pflege ihrer Habseligkeiten erheblich erleichtern, sei es bei der Vorbereitung auf eine Show auf der Bühne oder beim Schutz ihrer Besitztümer wie Accessoires und Schmuck vor auffälligen Handlungen.

Solche Schaumstoffe sind für Flightcases gedacht, also für Materialien, die in dieser kurzen Diskussion die größtmögliche Sicherheit dieser Wertgegenstände gewährleisten.

Gängige Schaumstoffe für Flightcases + ihre Anwendungen

Zu den am häufigsten verwendeten Schaumstoffen gehören solche für Flightcases, die Sie mitnehmen, um zu verhindern, dass Ihre Sachen in falsche Hände geraten. Es gibt verschiedene Arten. Erfahren Sie mehr über sie und ihre Einsatzmöglichkeiten:

1. Standard-Polyethylenschaum

Es ist ein geschlossenzelliges, langlebiges und leichtes Material für Flightcases und zeichnet sich durch seine hervorragende Stoß-, Wasser-, Chemikalien- und Vibrationsbeständigkeit aus. Es ist fester als Polyurethanschaum und eignet sich daher ideal für die Lagerung schwerer Geräte wie Waffen. Es ist zudem recycelbar.

2. Expandierter Polypropylenschaum

EPP eignet sich auch für leichte, geschlossenzellige Schaumstoffe für Flightcases. Sie sind zudem hochgradig stoßfest, langlebig und energieabsorbierend. Sie schützen zerbrechliche Gegenstände wie Küchenutensilien vor Stößen und Vibrationen, falls Sie beispielsweise Gläser mit auf den Flug nehmen möchten. Sie sind außerdem beständig gegen Wasser, Chemikalien und Öle und behalten auch nach einem Aufprall ihre Form. Sie zeichnen sich außerdem durch hervorragende Wärmedämmung und Recyclingfähigkeit aus.

3. Stratocell R-Schaum

Stratocell R-Schäume gehören zu den vertrauenswürdigsten Schaumstoffen für Flightcases Denn sie sind leicht und geschlossenzellig. Darüber hinaus bestehen sie zu mindestens 65 Prozent aus Recyclingmaterial und sind somit eine nachhaltige Wahl für solche Fälle.

Sie zeichnen sich durch hervorragende Polsterung und Aufprallschutz aus und schützen Ihre Gegenstände vor wiederholten Stößen, beispielsweise während des Fluges. Das Material ist außerdem abriebfest, wasserabweisend und isolierend und daher individuell anpassbar. Sie können sie auch recyceln!

4. Expandierter Polyethylenschaum

Was ist EPE-Schaum? Verwechseln Sie diesen EPE-Schaum nicht mit den anderen auf dieser Liste. EPE-Schaum wird aus Polyethylen niedriger Dichte hergestellt und zeichnet sich durch seine hohe Elastizität aus. Dadurch ist er flexibel und leicht und kann gebogen werden, um die auftretenden Kräfte zu absorbieren. Verwenden Sie ihn für unregelmäßig geformte Objekte, die von seiner Flexibilität profitieren. Darüber hinaus eignet sich seine Stoßdämpfung ideal für leichte Elektrogeräte.

5. Vernetzter Polyethylenschaum

Was ist XPE-Schaum? XPE-Schaumstoffe zeichnen sich durch eine hohe Stoßdämpfung aus und bieten Ihren Gegenständen die optimale Polsterung. Da sie meist wasser- und feuchtigkeitsbeständig sind, bieten sie optimalen Schutz vor Rost und verlängern so ihre Lebensdauer.

XPE-Schäume sind außerdem leicht und werden als Schaumstoffauskleidungen in Flightcases bevorzugt, da sie Stöße absorbieren können, schwer entflammbar sind, sich leicht anpassen lassen, sich leicht von Falten erholen, rutschfest und geruchslos sind und eine längere Haltbarkeit haben.

Direkter Vergleich: EPE-Schaum vs. XPE-Schaummaterialien

Beginnen wir mit dem EPE-Schaum. Dieser Schaum wird zur Herstellung von Yogamatten, Schienbeinschonern und Ähnlichem verwendet und zeichnet sich durch ein hohes Gewichts-Festigkeits-Verhältnis und eine hohe Wärmebeständigkeit aus. Das heißt, man kann ihn mehrmals erhitzen und schmelzen und ihn so zu neuen Objekten umformen.

Sie sind nicht nur beständig gegen Wasser, Öl und verschüttete Chemikalien, sondern nehmen auch nach Stößen und Erschütterungen schnell wieder ihre ursprüngliche Form an. Sie brechen, zersplittern oder zersplittern nicht – niemals.

Darüber hinaus sind sie wasserdicht. Sollten Restmaterialien übrig bleiben, können diese problemlos eingesammelt und recycelt werden, ohne den Schaumstoff zu beschädigen.

XPE-Schaum hingegen wird aus Polyethylenschaum geringer Dichte mit mehreren Filtern, chemischen Vernetzungs- und Treibmitteln hergestellt und eignet sich für den Bau von Materialien, bei denen Wärmedämmung, Feuchtigkeitsbeständigkeit, Vibrations- und Schallschutz entscheidend sind. Neben der Verwendung für Flightcases ist das Material auch in der Infrastrukturbranche nützlich.

Das Urteil

Die Wahl zwischen XPE und EPE hängt maßgeblich von der gewünschten Verwendung und dem Verwendungszweck ab. Für umfangreichere Anwendungen empfiehlt sich XPE-Schaum.

Sun Case Supply ist ein führendes Unternehmen Wo Sie diese Schaumstoffe beziehen können. Wir sind Hersteller von Koffern für Make-up, Werkzeuge, Waffen, Sportkarten, Tierpflegeprodukte und schwere Flugausrüstung.

Wenn Sie Ihr Gepäck von einem Land ins nächste transportieren, sollten Sie auf nichts verzichten. Worauf warten Sie also noch? Werfen Sie einen Blick in unseren Produktkatalog – von der Forschung und Entwicklung bis zur Verpackung – mit größter Sorgfalt hergestellt. Kontaktieren Sie uns noch heute für weitere Informationen.