Caixas de alumínio vs. plástico vs. madeira: uma comparação entre compradores B2B

Feeling confused due to balancing cost, durability, and aesthetics when choosing between aluminum, plastic, and wooden cases? You’re not alone; every B2B buyer faces the same dilemma.

Utilizing our extensive manufacturing expertise, our team of experts has broken down the basics for you.

Keep reading to uncover how aluminum, plastic, and wooden cases perform under real-world conditions, custom options for each, and much more.

Wood/ATA Cases: Traditional Look & Heavy-Duty Use

Heavy-Duty Use

Despite being heavier, their ability to handle heavy loads and rough usage makes them ideal for carrying large or expensive objects.

This is because the use of thick plywood or hardwood panels creates stronger shells that absorb shocks and are less prone to crushing.

Hence, they’re ideal applications that

Elegant and Traditional Look

Wood/ATA cases have a more classic aesthetic appeal to individuals who love classic or natural style.

The natural texture, patterns, grains, and colors that cannot be duplicated by synthetic materials.

This makes the case visually special and appears to be more than just a practical object.

Options for Custom Wood/ATA Cases

Interior Organization

These cases can also be customized with more organized interiors to make packing and unloading easier for clients, like:

- Divisores

- Removable trays

- Additional partitions

This also reduces the risk of misplaced items while protecting them.

Heavy-Duty Construction and Hardware Reinforcements

Their protection and durability can be further improved against rough handling and multiple deliveries through various reinforcements like:

- Thick plywood (at least 1 inch)

- Metal edge additions like steel corner brackets

- ABS lamination (minimum thickness of 0.04 inches)

This also helps the cases pass the ATA 300 standards, a necessity for commercial and industrial applications.

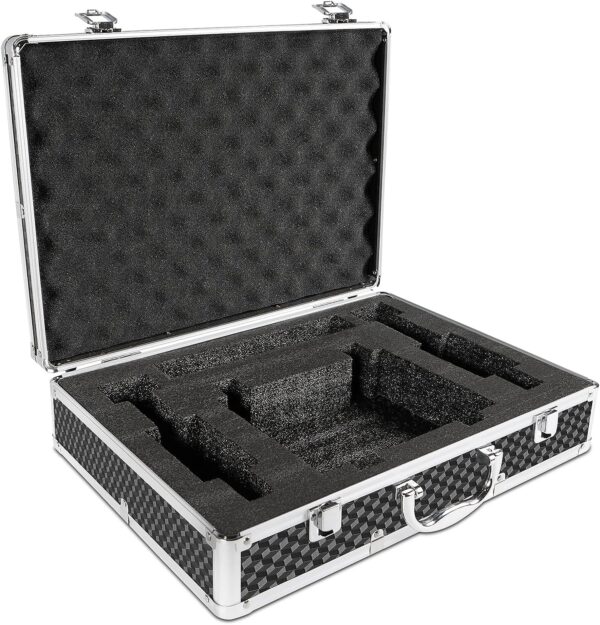

Aluminum Carrying Case: Strength, Lightweight, and Premium Feel

Durable, Lightweight, and Sleek Appearance

Caixas de alumínio have an attractive and modern style with a shining, polished finish that conveys quality and appeal!

Furthermore, they have low density and strong alloys that allow them to improve their properties. These cases made from aluminum have an excellent strength-to-weight ratio.

Hence, they’re easy to carry while being resistant to hits, cracks, and tears while keeping a luxurious feel, as described in our other aluminum carrying case guide.

Temperature Resistant and Corrosion Resistant

Studies also showed that aluminum has high thermal conductivity and spreads heat effectively.

These characteristics let the case protect items from extreme heat and cold temperatures without losing strength or becoming brittle.

As shown in our Gun Case Durability Test article, they also produce protective thin oxide layers.

This effectively prevents the case from rust and corrosion in most situations, including high humidity.

Options for Custom Hard Aluminum Case

There are plenty of customization choices available, such as precise sizes and features to meet unique needs.

Since aluminum cases are also remarkably easy to build,

Here are some of the custom hard aluminum case options for each type:

Custom Aluminum Flight Case

You can consider adding sturdy wheels and handles to make transporting big or bulky equipment easier.

To optimize your custom hard aluminum case for flight, try the following options:

- Tongue and groove valances

- Heavy-duty swivel casters and handles

- Shock absorption foams like PU or XPE

Custom Aluminum Shipping Cases

A custom hard aluminum case for shipping might have custom foam inside for shock absorption to protect fragile equipment during delivery.

Take into consideration extra traits that increase durability and branding, such as

- Custom packaging digital printing.

- Weatherproof sealing with rubber gaskets

- Lugs and tracks to prevent cases from sliding or falling when stacked

- Aluminum frames combined with ABS or laminated fireproof plywood for durability

Durable Protective Aluminum Carrying Case

To make your custom hard aluminum case more reliable, have its components welded together to boost structural strength, durability, and hardness while staying lightweight.

Try some of these choices to further improve your aluminum carrying case:

- Recessed latches

- Finishes like anodizing

- Reinforced framing, like thicker sections

- Design elements that meet or exceed military or industrial standards (e.g., fully welded joints)

Hard Plastic: Lightweight, Extreme Durability & Waterproofing

Waterproofing Capabilities

Apart from their sleek and sturdy designs, their outer thick shell prevents water and moisture from entering.

This made them ideal to use for any kind of weather.

Lightweight and Extreme Durability

Hard plastic suitcases are usually made from polycarbonate (PC) ou polypropylene (PP), which are recognized for their strength and flexibility.

This increased their durability against cracking and severe handling, like being dropped.

They are also very light to carry and use for travel; for example, the denser material polycarbonate still weighs only 1.18-1.22 g/cm³.

Options for Custom Hard Plastic Cases

They are the simplest to construct, which permits a wide range of practical and aesthetic changes to hard plastic cases to make them more unique and functional.

Below are some of the custom options available besides customizable colors and finishes:

Alças

Hard plastic case handles can be best constructed from materials such as:

- Alumínio

- Polyethylene

- Polipropileno

- Polyvinyl Chloride

- Ergonomic rubber

They can be telescopic, single, or double-pole designs based on the user’s preferred extent of stability and mobility.

Lock Customization

Custom hard plastic containers can be integrated with Fechaduras aprovadas pela TSA ou personalized locking devices, and these are useful for consumers transporting crucial items.

Surface Customization

Hard plastic cases can be tailored with customized designs, patterns, or even artwork created onto the shell using full-bleed printing.

This lets you put images, logos, and personalized graphics on your baggage.

Aluminum vs. Plastic vs. Wooden Cases: Ideal Applications.

Aluminum, plastic, and wooden cases have their respective ideal uses due to their material properties, which are some of them below:

Aluminum Carrying Cases

Outdoor Uses

Aluminum cases can handle weather more effectively and are more resistant to corrosion and rust compared to the other cases.

This makes it perfect for outside uses where portability and protection are crucial.

This includes picnics and camping.

Travel and Transport

They’re lightweight yet durable.

Aluminum cases offer great damage protection, which makes them suitable for regular travelers or users that need maximum durability for their fragile items.

High-End Gifting or Presentation

Aluminum cases are perfect for fashionable showcasing and gifting because of their clean surfaces and can have luxurious interiors or exteriors.

Wooden Cases

Long-Term Presentation and Storage

Wood has strong protection through good insulation too.

This helps them keep the items warm or cool as needed.

So, they’re ideal for items stored in cellars, displays, or offices

Hard Plastic Cases

Everyday Business Use and Events

They’re easy to clean, handle, and moisture-resistant.

As a result, they can be utilized for meetings, exhibitions, and other events that require only moderate protection.

Head-to-Head Comparison: Final Verdicts

Peso

Wood ATA cases are heavier due to the wood’s material properties.

While modern aluminum case designs can be designed to be lighter, they are still heavier than hard plastic.

If weight is an important consideration, choose hard plastic cases because they are the lightest of the three.

Durabilidade

Alumínio is the most durable and has more impact resistance because of its material properties, frame, and construction methods.

Hard plastic cases offer excellent shock protection as well.

However, they’re susceptible to extreme situations that lead to cracks or chips, like sharp, heavy impacts.

Finally, wood ATA cases can be sturdy.

But they may be prone to harm from both impacts and moisture if not properly maintained.

Cost and Total Cost of Ownership

Hard plastic cases are mostly the most affordable and have fewer maintenance costs.

This can further be lowered as many models provide waterproof and dustproof features.

Wood cases can be costly initially.

Although they need additional care and their susceptibility to moisture damage raises maintenance costs.

Meanwhile, caixas de alumínio have the most expensive initial cost.

Fortunately, they have a longer lifespan and can have enhanced features that further justify investment, like

- Dustproof

- Waterproof

- Corrosion resistant

Customization and Design Flexibility

Custom hard plastic cases are the most flexible, with various colors, textures, and interior designs available.

This is because they’re easy to mold into different shapes and colored in many ways.

While custom hard aluminum cases offer limited customization, foam inserts and finishes are more often available.

Wood casings have limited customizing options because of their material qualities, manufacturing difficulty, and greater weight.

Sources:

Science Direct Researches on Aluminum

Benefits of an Aluminum Framing System

The Endless Benefits of Aluminum Custom Cases

Polypropylene vs Polycarbonate:Main Differences